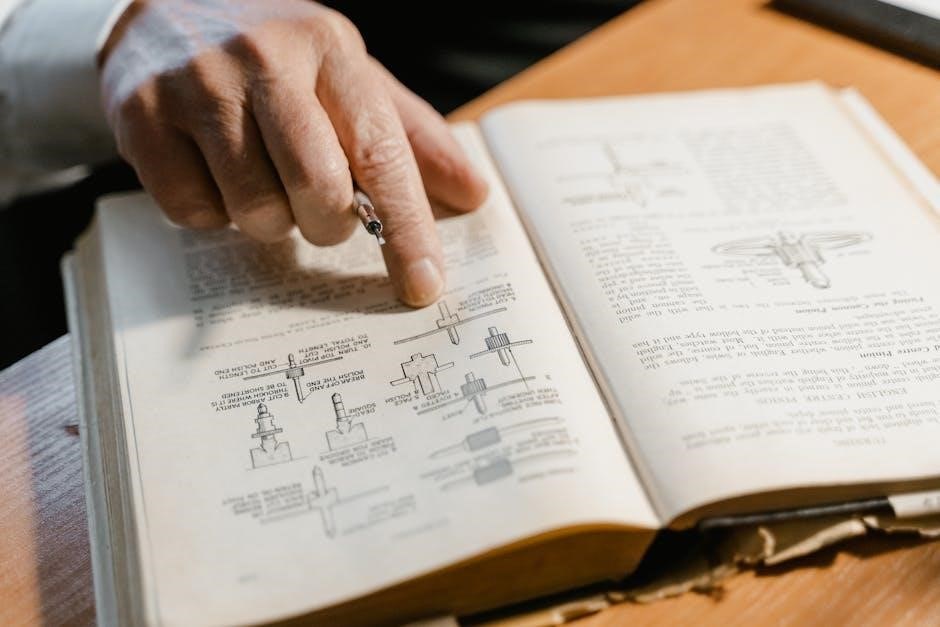

Lewis Pumps Instruction Manual: A Comprehensive Guide

Lewis pumps, including models like MTH-2278 and the LPN series, require careful operation; this manual details installation, maintenance, and safety for optimal performance․

Understanding Lewis Pump Models

Lewis pumps encompass a diverse range, from vertical centrifugal designs specifically engineered for sulphur handling to robust irrigation and general industrial applications․ Key classifications include submerged-bearing and cantilever shafted models, offering solutions for varied operational demands․ The Model 50 series, alongside the LPN series – a between-bearing, axially split pump – demonstrates this breadth․

Understanding these distinctions is crucial for selecting the appropriate pump for your specific needs, ensuring efficient and reliable performance․ Heavy-duty construction is a hallmark, particularly in slurry pump applications like the Goulds Model XHD․

Identifying Your Specific Pump Model

Accurate model identification is paramount for accessing correct documentation and spare parts․ Lewis pumps utilize designations like MTH-2278, MTH36512, and the LPN series․ Locate the pump’s nameplate, typically affixed to the volute casing, which displays critical information including flow rate (e․g․, 610m3/h), speed (e․g․, 1480 RPM), and impeller diameter (e․g․, 298mm)․

If the nameplate is damaged or illegible, consult previous records or contact Lewis support, providing any available details to facilitate accurate identification․

Lewis Pump Applications

Lewis pumps demonstrate versatility across diverse industrial sectors․ They are specifically engineered for demanding applications like sulphur handling, utilizing vertical centrifugal designs optimized for this corrosive material․ Furthermore, Lewis pumps excel in irrigation, with models like the Kelly and Lewis Model 50 series providing substantial flow rates (e․g․, 500 GPM at 240ft head)․

Beyond these, they serve general industrial needs, offering reliable fluid transfer solutions․

Sulphur Handling Pumps

Lewis vertical centrifugal pumps are specifically engineered for sulphur handling, designed as steam-jacketed units to maintain optimal temperatures and prevent solidification․ These pumps address the unique challenges posed by molten sulphur’s corrosive nature and viscosity․ The robust construction ensures reliable operation in demanding environments․

These engineered-to-order pumps meet a variety of application requirements within the sulphur processing industry, offering durable and efficient performance․

Irrigation Pumps

Lewis offers irrigation pumps, such as the Kelly and Lewis Model 50 series 6, a 4×5 inch centrifugal pump designed for efficient water delivery․ These pumps feature a 15-inch full-size impeller and packed gland construction․

A capacity of 500 GPM at 240ft head requires a 50hp motor, demonstrating their power and suitability for large-scale agricultural applications․ Proper installation and maintenance are crucial for maximizing performance and longevity in irrigation systems․

General Industrial Use

Lewis vertical centrifugal pumps are engineered-to-order for diverse industrial applications, showcasing robust construction and adaptability․ These pumps handle various fluids, offering solutions beyond specialized areas like sulphur handling․

The LPN series, a between-bearing, axially split pump with a double suction impeller, exemplifies their versatility for medium-pressure applications․ Careful consideration of fluid properties and operating conditions is vital for selecting the appropriate Lewis pump for general industrial needs․

Pump Components and Their Functions

Lewis pumps utilize key components for efficient operation, including impellers – with diameters like 298mm – and volute casings․ Impeller type significantly impacts performance․ Bearing design is crucial; models feature submerged or cantilever shaft configurations, influencing maintenance requirements․

Understanding these elements is vital for proper installation and troubleshooting․ The interaction between the impeller and volute casing generates flow, while bearings ensure smooth shaft rotation, contributing to overall pump reliability and longevity․

Impeller Specifications (Diameter & Type)

Lewis pump impellers are critical for fluid movement, with diameters varying by model – for example, the Kelly and Lewis Model 50 series utilizes a 15-inch impeller․ Impeller type, whether open, semi-open, or closed, dictates handling capabilities․

A 298mm diameter is noted in some models (MTH-2278)․ Selection depends on the fluid’s viscosity and solids content․ Proper impeller specification ensures optimal flow rates and pressure, maximizing pump efficiency and minimizing wear, crucial for sulphur handling and irrigation applications․

Volute Casing Details

The volute casing in Lewis pumps is engineered to efficiently collect fluid discharged by the impeller, converting velocity energy into pressure․ Models like the MTH36512 utilize a volute, though specific material information isn’t always readily available․

Casing design impacts pump performance; proper volute geometry minimizes turbulence and maximizes hydraulic efficiency․ Construction materials are selected based on the pumped fluid’s corrosiveness, particularly vital for sulphur handling․ Regular inspection for wear or erosion is essential for maintaining optimal pump operation․

Bearing Types: Submerged vs․ Cantilever

Lewis pumps employ two primary bearing configurations: submerged and cantilever․ Submerged-bearing models feature bearings immersed in the pumped fluid, requiring lubrication and sealing for protection․ Cantilever shafted models, conversely, support the shaft externally, eliminating fluid contact with the bearings․

Heavy-duty construction often favors cantilever designs, avoiding issues associated with submerged bearings in abrasive slurries․ Selection depends on application demands; submerged bearings suit cleaner fluids, while cantilever designs excel in harsh environments, offering increased reliability․

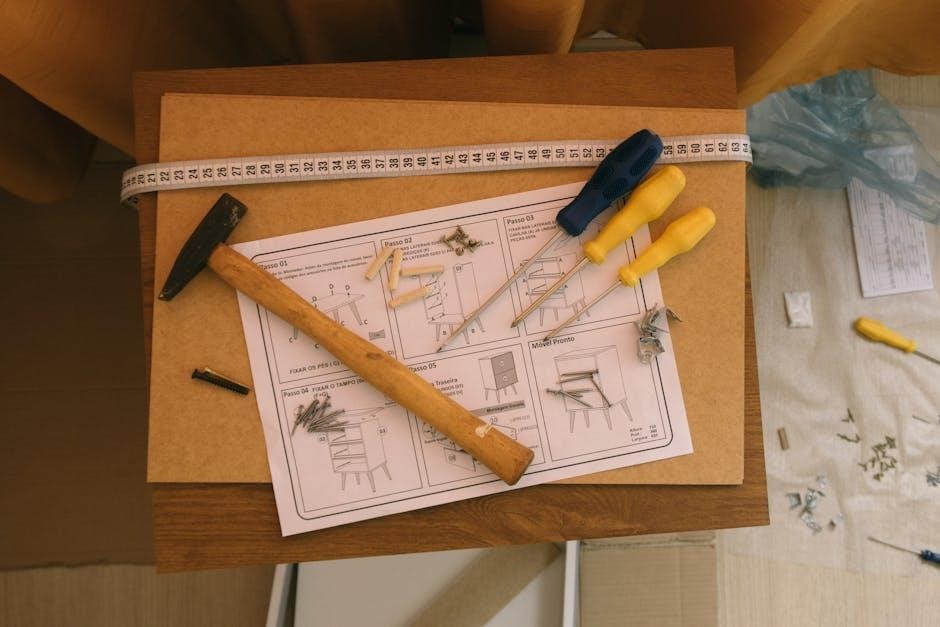

Installation Procedures

Proper Lewis pump installation is crucial for reliable operation․ Begin with pre-installation checks, verifying component integrity and ensuring alignment with piping systems․ Careful pump alignment and secure mounting are essential to prevent vibration and premature wear․

Follow manufacturer specifications for baseplate leveling and grout application․ Ensure adequate space for maintenance access․ Incorrect installation can lead to reduced efficiency, increased noise, and potential pump failure; therefore, meticulous attention to detail is paramount throughout the process․

Pre-Installation Checks

Before installing your Lewis pump, thoroughly inspect all components for shipping damage; Verify the pump model matches the order and application requirements․ Confirm the motor voltage and phase are compatible with the power supply․

Check the impeller for free rotation and ensure all fasteners are present․ Inspect gaskets and seals for proper condition․ Confirm adequate suction lift and discharge head calculations are correct․ These checks minimize potential issues during startup and ensure long-term reliability․

Pump Alignment and Mounting

Proper pump alignment is crucial for preventing premature bearing failure and ensuring efficient operation․ Utilize a laser alignment tool to achieve precise coupling alignment between the pump and motor shafts․ Mount the pump on a stable, level foundation capable of supporting its weight and operational vibrations․

Ensure adequate clearance around the pump for maintenance access․ Securely fasten the pump to the base using appropriate anchor bolts․ Verify the alignment after tightening bolts, as adjustments may be needed․

Operational Guidelines

Before starting the Lewis pump, verify all connections and ensure the suction line is fully primed․ Initiate the pump following the manufacturer’s start-up procedures, gradually increasing speed to the desired RPM – typically 1480 RPM for models like MTH-2278․

Continuously monitor flow rate and pressure during operation․ Deviations from expected performance may indicate issues requiring immediate attention․ Regular checks are vital for sustained, reliable performance of these engineered-to-order pumps․

Start-up Procedures

Prior to initiating a Lewis pump, confirm adequate lubrication and inspect for any obstructions․ Slowly open the suction valve while ensuring the discharge valve remains closed, allowing the pump to prime correctly․ Gradually increase the pump’s speed, monitoring amperage draw and bearing temperatures․

For sulphur handling pumps, verify steam jacket operation if applicable․ Avoid sudden starts or rapid speed changes, as these can induce stress on components․ Consistent monitoring during initial operation is crucial for optimal performance․

Monitoring Pump Performance (Flow Rate & Pressure)

Regularly assess flow rate and discharge pressure using installed gauges to ensure operation within specified parameters for your Lewis pump model․ Deviations from expected values may indicate impeller wear, valve restrictions, or system issues․ Track these readings over time to establish a baseline for performance evaluation․

Consistent monitoring aids in proactive maintenance, preventing unexpected failures and optimizing pump efficiency․ Note any unusual noises or vibrations alongside pressure and flow data․

Maintenance and Troubleshooting

Consistent inspection is crucial for Lewis pump longevity․ Regularly check for leaks, unusual noises, and excessive vibration․ A checklist should include bearing lubrication, impeller examination, and casing integrity․ Common issues like low flow often stem from impeller wear or blockage․ Noise can indicate cavitation or misalignment․

Address these promptly to prevent further damage․ Refer to the detailed troubleshooting section for specific solutions and always prioritize safety during maintenance procedures․

Regular Inspection Checklist

Prioritize a weekly visual inspection for leaks around the pump casing, piping connections, and seals․ Monthly, check bearing temperatures and lubrication levels – ensure proper function․ Quarterly, examine the impeller for wear, corrosion, or blockage, noting any performance decline․ Annually, a full system assessment is vital․

Verify proper alignment and mounting stability․ Document all findings and address any issues immediately to maintain optimal pump efficiency and prevent costly repairs․

Common Issues and Solutions (e․g․, Low Flow, Noise)

Low flow often indicates impeller wear, blockage, or air ingress – inspect and clear obstructions․ Excessive noise can stem from cavitation, misalignment, or bearing failure; check alignment and bearing condition․ If encountering either, immediately shut down the pump․

Vibration suggests imbalance; address promptly․ Regular maintenance, as outlined in the inspection checklist, prevents these issues․ Consult a qualified technician for complex problems․

Safety Precautions

Electrical safety is paramount: disconnect power before any maintenance․ Ensure proper grounding and adhere to all local electrical codes․ Mechanical safety requires caution around rotating parts; never operate with guards removed․ Always wear appropriate personal protective equipment (PPE), including eye protection and gloves․

Lockout/tagout procedures are essential during servicing․ Never attempt repairs beyond your skill level; consult qualified personnel․ Prioritize a safe working environment at all times․

Electrical Safety

Lewis pump electrical systems demand strict adherence to safety protocols․ Always disconnect power at the source before conducting any inspection or maintenance․ Verify proper grounding to prevent electrical shock hazards․ Inspect wiring for damage regularly, replacing worn or frayed cables immediately․

Ensure all electrical connections are secure and conform to local electrical codes․ Qualified personnel should handle complex electrical repairs․ Never operate the pump with damaged electrical components․

Mechanical Safety

Lewis pump mechanical components operate with significant force; prioritize safety․ Before maintenance, ensure the pump is fully isolated and depressurized․ Never remove guards or safety devices while the pump is running․ Regularly inspect couplings, bearings (submerged or cantilever), and the impeller for wear or damage․

Avoid loose clothing or jewelry near rotating parts․ Use appropriate personal protective equipment, including safety glasses and gloves․ Report any unusual vibrations or noises immediately to prevent potential failures․

Spare Parts and Ordering Information

To ensure optimal Lewis pump performance, use only genuine Lewis replacement parts․ When ordering, provide the complete pump model number (e․g․, MTH-2278) and the specific part description․ Critical components like impellers (298mm diameter examples exist), volute casings, and bearing assemblies are readily available․

Contact our support team with your pump’s serial number for assistance identifying the correct parts․ Detailed parts lists are available upon request, facilitating efficient maintenance and minimizing downtime․

Technical Specifications (Example: MTH-2278)

The Lewis MTH-2278 pump boasts a flow rate of 610 m³/h and operates at 1480 RPM․ It features a 298mm diameter impeller․ While specific material details for volute casings (like MTH36512) may vary, construction prioritizes durability․ These vertical centrifugal pumps are engineered-to-order, often steam-jacketed for specialized applications like sulphur handling․

Further specifications, including power requirements and pressure capabilities, are available in the complete product documentation․ Contact Lewis for detailed performance curves․

Goulds Model XHD Comparison

The Goulds Model XHD is a heavy-duty slurry pump, often considered alongside Lewis pumps for demanding industrial applications․ While both offer robust construction, Lewis specializes in engineered-to-order solutions, particularly for sulphur handling, with steam-jacketed options not commonly found in the XHD series․

Lewis pumps, like the LPN series, may offer advantages in specific flow and pressure requirements․ A direct comparison requires detailed application analysis and consideration of total cost of ownership․

LPN Pump Series Overview

The Lewis LPN pump series represents a between-bearing, axially split, single-stage centrifugal pump design․ Featuring a double-suction impeller and side-side nozzles, the LPN excels in medium-pressure applications․ This configuration enhances hydraulic performance and simplifies maintenance access․

Designed for versatility, the LPN series handles various fluids efficiently․ Its robust construction ensures reliability in demanding industrial environments, making it a valuable asset for diverse pumping needs․

Resources and Support

Lewis pumps are engineered-to-order, and our dedicated team provides comprehensive support throughout the pump’s lifecycle․ We are committed to assisting customers, regardless of location, with any inquiries or challenges they may encounter․ Access detailed product specifications for Lewis vertical sulphur pumps online․

For further assistance, including spare parts ordering (like those for model MTH-2278) and troubleshooting, please contact our technical support team․ We strive to ensure seamless operation and maximum uptime for your Lewis pump․

Leave a Reply